Lamination

Design approach for modelling and design of 3D-parts

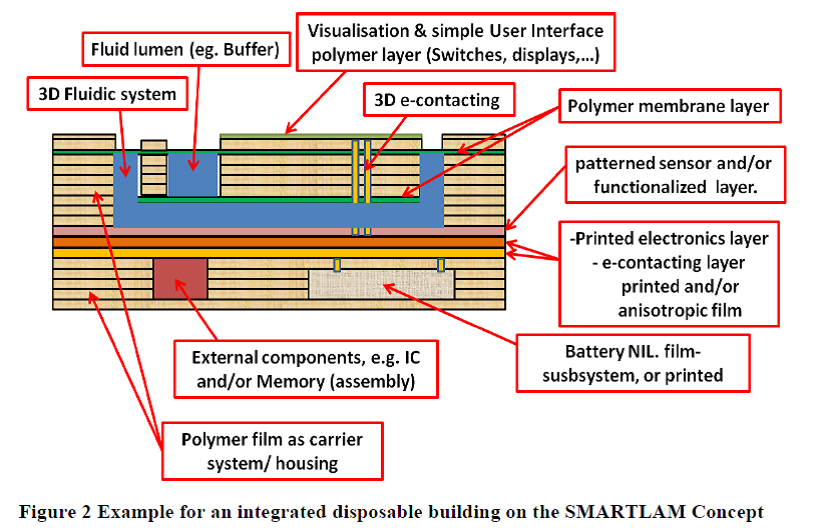

Two new inter-dependent groundbreaking concepts are integral to the SMARTLAM Production philosophy:

- 3D integrated Design approach (3D-I) for micro-products and for micro-manufacture. To achieve this vision, a new manufacturing approach, based on a combination of laminating technologies known from the Rapid Prototyping with handling of discrete parts and advanced surface coating (aerosol jet) and patterning technologies (laser structuring/ cutting/modification) in a micro and nano scale will be developed based on the seamless adaption, further development and integration of already established micro additive and subtractive processes into a common manufacturing platform, revolutionising both design and production.

-

3D integrated Manufacturing approach: The 3D integrated Manufacturing approaches address the material and technology integration where SMARTLAM transcends the separation between function related manufacturing steps and the required process chain capabilities. The following three classes of functions shall be adapted and integrated in the SMARTLAM 3D integrated Manufacturing approach:

- polymer film laminating, structuring, modification, welding, cutting and handling

- printing technologies for antennas, batteries and 3D-contacting

- micro positioning of remaining discrete parts that cannot be substituted by printed or nano structured films